|

| March 03, 2020 | Volume 16 Issue 09 |

Mechanical News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New nylon constant torque hinge

Southco has expanded its line of E6 Constant Torque Hinges with a compact, nylon version designed for small applications. The newest addition to the company's E6 50 Constant Torque Position Control Hinge series measures 45 mm with a torque range of 4 to 16 in./lb and is 65% lighter compared to the standard E6 50 Hinge. It provides constant resistance throughout the entire range of motion, enabling users to easily position doors, display screens, and other mounted components and hold them securely at any desired angle.

Southco has expanded its line of E6 Constant Torque Hinges with a compact, nylon version designed for small applications. The newest addition to the company's E6 50 Constant Torque Position Control Hinge series measures 45 mm with a torque range of 4 to 16 in./lb and is 65% lighter compared to the standard E6 50 Hinge. It provides constant resistance throughout the entire range of motion, enabling users to easily position doors, display screens, and other mounted components and hold them securely at any desired angle.

Learn more.

What injection molding material do I use?

How do you decide what type of plastic to use for your next injection molding project? Xometry can help you narrow your choices. Discover the different strengths and applications for materials that could be ideal for your application by learning about the most common plastic injection molding materials in detail.

How do you decide what type of plastic to use for your next injection molding project? Xometry can help you narrow your choices. Discover the different strengths and applications for materials that could be ideal for your application by learning about the most common plastic injection molding materials in detail.

Read this detailed Xometry article.

What are carbon composite bellows springs?

The Carbon Composite Bellows Spring (CCBS) from MW Components is a system of carbon fiber elements that combine to work as a high-performance, lightweight, and design-flexible compression spring meant to replace coil springs or metallic Belleville disc springs. A functional spring is made from several individual elements paired and joined to make a stack. The stack spring rate is determined by the number of elements, the base rate of each element, and their series or parallel orientation in the stack. Applications include motorsports, aerospace, and high-performance activities.

The Carbon Composite Bellows Spring (CCBS) from MW Components is a system of carbon fiber elements that combine to work as a high-performance, lightweight, and design-flexible compression spring meant to replace coil springs or metallic Belleville disc springs. A functional spring is made from several individual elements paired and joined to make a stack. The stack spring rate is determined by the number of elements, the base rate of each element, and their series or parallel orientation in the stack. Applications include motorsports, aerospace, and high-performance activities.

Learn more.

Conductive Brush Ring overcomes current leakage in EV powertrains

SKF's new Conductive Brush Ring paves the way to greater reliability and longer life in high-performance electric vehicle powertrain systems. Using pure carbon fiber bristles, it provides a reliable electrical connection between an EV eAxle rotor shaft and its housing. When used in combination with SKF Hybrid ceramic ball bearings, it helps to alleviate parasitic current effects that can lead to premature failure in bearings and other components. Available in different configurations for wet (oil-lubricated) motor designs -- and soon for dry (sealed) applications.

SKF's new Conductive Brush Ring paves the way to greater reliability and longer life in high-performance electric vehicle powertrain systems. Using pure carbon fiber bristles, it provides a reliable electrical connection between an EV eAxle rotor shaft and its housing. When used in combination with SKF Hybrid ceramic ball bearings, it helps to alleviate parasitic current effects that can lead to premature failure in bearings and other components. Available in different configurations for wet (oil-lubricated) motor designs -- and soon for dry (sealed) applications.

Learn more.

hyperMILL 2024 CAD/CAM software suite

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

OPEN MIND Technologies has introduced its latest hyperMILL 2024 CAD/CAM software suite, which includes a range of powerful enhancements to its core toolpath capabilities, as well as new functionality for increased NC programming efficiency in applications ranging from 2.5D machining to 5-axis milling. New and enhanced capabilities include: Optimized Deep Hole Drilling, a new algorithm for 3- and 5-axis Rest Machining, an enhanced path layout for the 3D Plane Machining cycle, better error detection, and much more.

Learn more.

One-part epoxy changes from red to clear under UV

Master Bond UV15RCL is a low-viscosity, cationic-type UV-curing system with a special color-changing feature. The red material changes to clear once exposed to UV light, indicating that there is UV light access across the adhesive material. Although this change in color from red to clear does not indicate a full cure, it does confirm that the UV light has reached the polymer. This epoxy is an excellent electrical insulator. UV15RCL adheres well to metals, glass, ceramics, and many plastics, including acrylics and polycarbonates.

Master Bond UV15RCL is a low-viscosity, cationic-type UV-curing system with a special color-changing feature. The red material changes to clear once exposed to UV light, indicating that there is UV light access across the adhesive material. Although this change in color from red to clear does not indicate a full cure, it does confirm that the UV light has reached the polymer. This epoxy is an excellent electrical insulator. UV15RCL adheres well to metals, glass, ceramics, and many plastics, including acrylics and polycarbonates.

Learn more.

SPIROL Press-N-Lok™ Pin for plastic housings

The Press-N-Lok™ Pin was designed to permanently retain two plastic components to each other. As the pin is inserted, the plastic backfills into the area around the two opposing barbs, resulting in maximum retention. Assembly time is quicker, and it requires lower assembly equipment costs compared to screws and adhesives -- just Press-N-Lok™!

The Press-N-Lok™ Pin was designed to permanently retain two plastic components to each other. As the pin is inserted, the plastic backfills into the area around the two opposing barbs, resulting in maximum retention. Assembly time is quicker, and it requires lower assembly equipment costs compared to screws and adhesives -- just Press-N-Lok™!

Learn more about the new Press-N-Lok™ Pin.

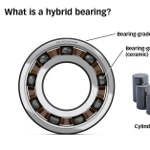

Why hybrid bearings are becoming the new industry standard

A combination of steel outer and inner rings with ceramic balls or rollers is giving hybrid bearings unique properties, making them suitable for use in a wide range of modern applications. SKF hybrid bearings make use of silicon nitride (twice as hard as bearing steel) rolling elements and are available as ball bearings, cylindrical roller bearings, and in custom designs. From electric erosion prevention to friction reduction and extended maintenance intervals, learn all about next-gen hybrid bearings.

A combination of steel outer and inner rings with ceramic balls or rollers is giving hybrid bearings unique properties, making them suitable for use in a wide range of modern applications. SKF hybrid bearings make use of silicon nitride (twice as hard as bearing steel) rolling elements and are available as ball bearings, cylindrical roller bearings, and in custom designs. From electric erosion prevention to friction reduction and extended maintenance intervals, learn all about next-gen hybrid bearings.

Read the SKF technical article.

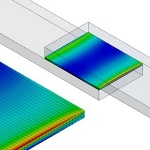

3M and Ansys train engineers on simulating adhesives

Ansys and 3M have created an advanced simulation training program enabling engineers to enhance the design and sustainability of their products when using tapes and adhesives as part of the design. Simulation enables engineers to validate engineering decisions when analyzing advanced polymeric materials -- especially when bonding components made of different materials. Understand the behavior of adhesives under real-world conditions for accurate modeling and design.

Ansys and 3M have created an advanced simulation training program enabling engineers to enhance the design and sustainability of their products when using tapes and adhesives as part of the design. Simulation enables engineers to validate engineering decisions when analyzing advanced polymeric materials -- especially when bonding components made of different materials. Understand the behavior of adhesives under real-world conditions for accurate modeling and design.

Read this informative Ansys blog.

New FATH T-slotted rail components in black from AutomationDirect

Automation-Direct has added a wide assortment of black-colored FATH T-slotted hardware components to match their SureFrame black anodized T-slotted rails, including: cube connectors (2D and 3D) and angle connectors, joining plates of many types, brackets, and pivot joints. Also included are foot consoles, linear bearings in silver and black, cam lever brakes, and L-handle brakes. FATH T-slotted hardware components are easy to install, allow for numerous T-slotted structure configurations, and have a 1-year warranty against defects.

Automation-Direct has added a wide assortment of black-colored FATH T-slotted hardware components to match their SureFrame black anodized T-slotted rails, including: cube connectors (2D and 3D) and angle connectors, joining plates of many types, brackets, and pivot joints. Also included are foot consoles, linear bearings in silver and black, cam lever brakes, and L-handle brakes. FATH T-slotted hardware components are easy to install, allow for numerous T-slotted structure configurations, and have a 1-year warranty against defects.

Learn more.

Weird stuff: Moon dust simulant for 3D printing

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Crafted from a lunar regolith simulant, Basalt Moon Dust Filamet™ (not a typo) available from The Virtual Foundry closely mirrors the makeup of lunar regolith found in mare regions of the Moon. It enables users with standard fused filament fabrication (FFF) 3D printers to print with unparalleled realism. Try out your ideas before you go for that big space contract, or help your kid get an A on that special science project.

Learn more.

Break the mold with custom injection molding by Rogan

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more.

With 90 years of industry experience, Rogan Corporation possesses the expertise to deliver custom injection molding solutions that set businesses apart. As a low-cost, high-volume solution, injection molding is the most widely used plastics manufacturing process. Rogan processes include single-shot, two-shot, overmolding, and assembly. Elevate your parts with secondary operations: drilling and tapping, hot stamping, special finishes, punch press, gluing, painting, and more.

Learn more.

World's first current-carrying fastening technology

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

PEM® eConnect™ current-carrying pins from Penn-Engineering provide superior electrical connections in applications that demand high performance from internal components, such as automotive electronics. This first-to-market tech provides repeatable, consistent electrical joints and superior installation unmatched by traditional fastening methods. Features include quick and secure automated installation, no hot spots or poor conductivity, and captivation options that include self-clinching and broaching styles.

Learn more about eConnect pins.

New interactive digital catalog from EXAIR

EXAIR's latest catalog offers readers an incredible source of innovative solutions for common industrial problems like conveying, cooling, cleaning, blowoff, drying, coating, and static buildup. This fully digital and interactive version of Catalog 35 is designed for easy browsing and added accessibility. Customers can view, download, print, and save either the full catalog or specific pages and sections. EXAIR products are designed to conserve compressed air and increase personnel safety in the process. Loaded with useful information.

EXAIR's latest catalog offers readers an incredible source of innovative solutions for common industrial problems like conveying, cooling, cleaning, blowoff, drying, coating, and static buildup. This fully digital and interactive version of Catalog 35 is designed for easy browsing and added accessibility. Customers can view, download, print, and save either the full catalog or specific pages and sections. EXAIR products are designed to conserve compressed air and increase personnel safety in the process. Loaded with useful information.

Check out EXAIR's online catalog.

5 cost-saving design tips for CNC machining

Make sure your parts meet expectations the first time around. Xometry's director of application engineering, Greg Paulsen, presents five expert tips for cutting costs when designing custom CNC machined parts. This video covers corners and radii, designing for deep pockets, thread depths, thin walls, and more. Always excellent info from Paulsen at Xometry.

Make sure your parts meet expectations the first time around. Xometry's director of application engineering, Greg Paulsen, presents five expert tips for cutting costs when designing custom CNC machined parts. This video covers corners and radii, designing for deep pockets, thread depths, thin walls, and more. Always excellent info from Paulsen at Xometry.

View the video.

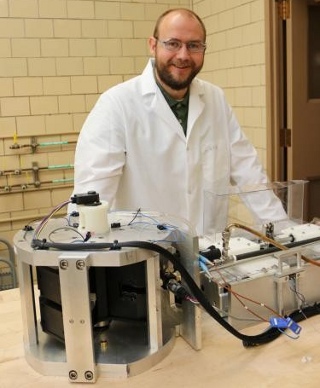

Ames Lab's testing device speeds the way to new refrigeration technology

Postdoctoral researcher Lucas Griffith with CaloriSMART (Caloric Small-scale Modular Advanced Research Test-stand), a one-of-a-kind system that is being used to rapidly test new materials for an entirely new kind of refrigeration technology. [Credit: U.S. Department of Energy, Ames Laboratory]

The U.S. Department of Energy's Ames Laboratory is employing a testing device that pairs materials science with engineering systems development. Called CaloriSMART (Caloric Small-scale Modular Advanced Research Test-stand), the one-of-a-kind system is being used to rapidly test new materials that might eventually be part of an entirely new kind of refrigeration technology for the 21st century and beyond.

Outdated cooling technology is one of the most pressing issues of a rapidly growing global population and the resulting environmental concerns.

"Gas compression cycle cooling is the standard used today; a very old and very mature technology," said Lucas Griffith, a postdoctoral researcher on the project. "We're reaching the point where we need the next big thing that could push beyond those limits, and we think magnetocaloric cooling has that ability."

A magnetocaloric cooling system uses an active solid, relying on reversible thermal phenomena to provide cooling and heating when a magnetic field around the solid varies. For the last 20 years, materials scientists have been searching for compounds that can generate strong thermal effects when cyclically acted upon. Finding promising magnetocaloric materials is a science discovery challenge that Ames Laboratory has been a leader in from the very beginning, when project leader Vitalij Pecharsky discovered the giant magnetocaloric effect in Gadolinium-Silicon-Germanium in 1996.

But the question of how those materials will perform in an actual refrigeration system is best answered through engineering, and that's where CaloriSMART comes in.

"We have always been at the top of the game in terms of materials discovery for this technology," said Pecharsky, "but over time we realized that the one thing that is really hanging this advancement up from getting to the deployment stage is the disconnect between materials discovery and systems engineering. Research in these two areas must go hand in hand in order for it to be successful. We built CaloriSMART three years ago, and it has put Ames in a unique place in the development of this technology."

The device is able to test materials' cooling capabilities using small quantities in just a few hours and is flexible enough to test the same material in different forms. The device has already demonstrated results that suggest the expected performance of a larger scale system, and helped scientists discover a new way of benchmarking the performance of magnetocaloric systems -- the exergetic power quotient.

Roughly comparable to SEER, the current industry standard of explaining energy efficiency in current gas compression technology, the idea behind the exergetic power quotient was suggested by Julie Slaughter, scientist for the project, and one of the designers of CaloriSMART.

"We need to be able to see how well we're using the most expensive component of the system, the magnetic field," said Slaughter. "Having a metric we can compare the performance of these systems against makes it easier to determine if we're getting the maximum performance out of the material, or whether we need to be looking at inefficiencies in the system."

The research is further discussed in the paper, "CaloriSMART: Small-scale test-stand for rapid evaluation of active magnetic regenerator performance," authored by Lucas Griffith, Agata Czernuszewicz, Julie Slaughter, and Vitalij Pecharsky; and published in Energy Conversion and Management.

The research is supported jointly by the Office of Energy Efficiency and Renewable Energy's Advanced Manufacturing Office (AMO) and Building Technologies Office (BTO). Ames Laboratory is a U.S. Department of Energy Office of Science National Laboratory operated by Iowa State University.

Source: Ames Laboratory

Published March 2020

Rate this article

View our terms of use and privacy policy